EnhanceMicroaAlgae partners at University of Manchester have developed a new optimised mixotrophic cultivation strategy for multi-product production that epitomises the microalgal biorefinery paradigm. The bioprocess yields enhanced biomass growth as well as significantly increased lipid and starch production. In addition, they have developed a new model of the process which can be used to optimally “tune” the bioprocess based on the bioproducts sought.

Their work entitled “Optimisation of microalgal cultivation via nutrient-enhanced strategies: the biorefinery paradigm” was recently published in Biotechnology for Biofuels (IF= 5.84) and is available in Open Source.

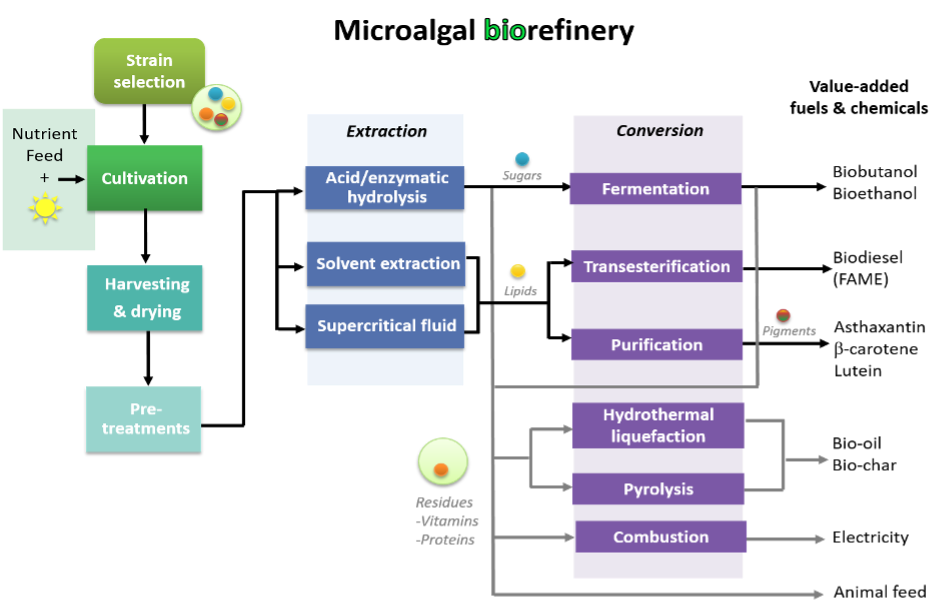

Background: The production of microalgal biofuels, despite their sustainable and renowned potential, is not yet cost‐effective compared to current conventional fuel technologies. However, the biorefinery concept increases the prospects of microalgal biomass as an economically viable feedstock suitable for the co‐production of multiple biofuels along with value‐added chemicals. To integrate biofuels production within the framework of a microalgae biorefinery, it is not only necessary to exploit multi‐product platforms, but also to identify optimal microalgal cultiva‐ tion strategies maximising the microalgal metabolites from which biofuels are obtained: starch and lipids. Whilst nutri‐ ent limitation is widely known for increasing starch and lipid formation, this cultivation strategy can greatly reduce microalgal growth. This work presents an optimisation framework combining predictive modelling and experimental methodologies to effectively simulate and predict microalgal growth dynamics and identify optimal cultivation strategies.

Results: Microalgal cultivation strategies for maximised starch and lipid formation were successfully established by developing a multi‐parametric kinetic model suitable for the prediction of mixotrophic microalgal growth dynamics co‐limited by nitrogen and phosphorus. The model’s high predictive capacity was experimentally validated against various datasets obtained from laboratory‐scale cultures of Chlamydomonas reinhardtii CCAP 11/32C subject to different initial nutrient regimes. The identified model‐based optimal cultivation strategies were further validated experi‐ mentally and yielded significant increases in starch (+ 270%) and lipid (+ 74%) production against a non‐optimised strategy.

Conclusions: The optimised microalgal cultivation scenarios for maximised starch and lipids, as identified by the kinetic model presented here, highlight the benefits of exploiting modelling frameworks as optimisation tools that facilitate the development and commercialisation of microalgae‐to‐fuel technologies.

Read this paper here.